QSA has the capabilities to develop 3D CFD models when it is required to assure and/or prove the quality of our equipment and process.

It concerns:

- The quench tank designs

- The graph of agitation FLOW inside the quench tank

- The temperature graph cross the section of part at selected time of process

- The evaluation of capabilities of quenching with the quenchant used

The use of those tools allows QSA to approach difficult quenching applications and make more reliable and customized the retrofit or new equipment we are offering to our customers. <br/>

3D CFD models have been used by QSA for applications as below :

• The reduction in distortions on parts

• The evaluation of quenching capabilities

• The improvement in homogeneity of quenching

• The improvement design of rack and fixtures

• The improvement of mechanical properties on quenched parts

• Ecc

Cooling rates simulations of stabilized bar in quenching oil.

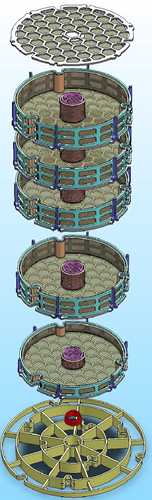

QSA has been called for evaluation of existing quenching capabilities on new nuclear ferule using bigger thickness of more than 40 mm from what it was.

Our calculations of existing water quenching on site demonstrated that the new specifications in terms of cooling rate at 1/2 thickness which was asking the customer were not achievable in those existing conditions .QSA provided one customized retrofit solution to achieve the new specs .

The solution has been developed and checked based on our 3D CFD models.

Improvement in components loading and handling the rack with improvement of life time of fixture by 40%