3D Design Technologies.

3D Design Technologies

3D Design Technologies

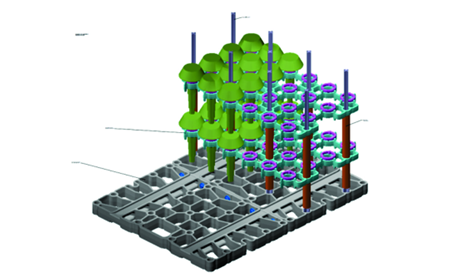

Carburized pinions application

Carburized pinions application

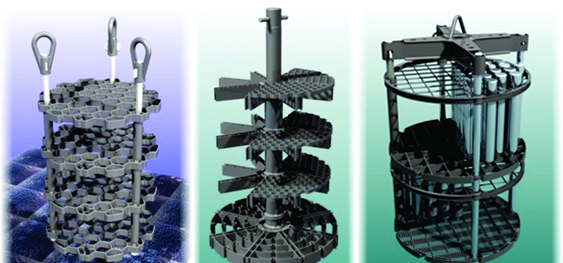

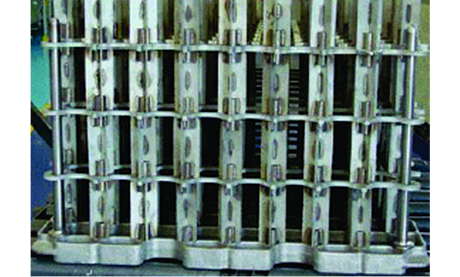

Loading fixture for sealed quench carburizing furnace

Loading fixture for sealed quench carburizing furnace

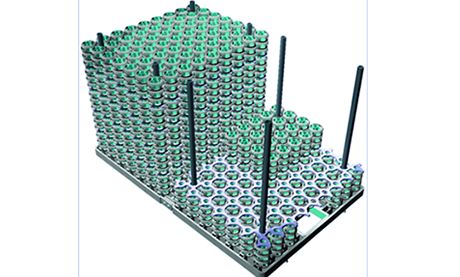

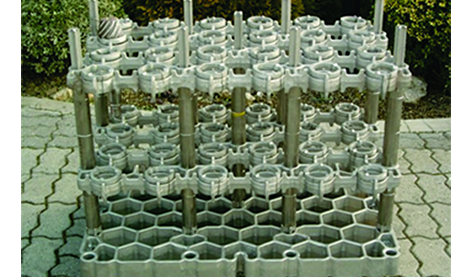

Carburized pinions Racks

Carburized pinions Racks

Most of the time in carburizing process several problems are always there due to use of standard old fashion techniques . It concerns the problems below but not only these :

- Distortions of parts

- Low hardening efficiency

- Time of loading / unloading

- Short life time of the racks / fixtures

- High drag out of quenchant - High weight of racks ( need more gas to heat metal which is not on the part but on the rack …)

By its unique approach of the matter, QSA and its well known partner TECNOALLOY ( rack & fixture manufacturer in Italy) with their customized solution have been able to provide to its different customers customized solutions to address all or most of these issues.

The success of our approach has been possible by a unique and smart approach combining :

• The use of the latest techniques of fabrication ( avoiding casting as much as possible and replacing it by welded structure , water cut only, with guaranty of longer life time )

• The grades of steel which respond better to the final use.

• The use of limited dimensions rack components to give them a longer life.

• The use of proper thickness of components ( Weight of rack lighter = to get always savings on gas consumption)

• The 3D simulations of flow to assure a more homogenous quenching of parts inside the rack = Better quenching quality and at same time less drag out.

Wherever, QSA has been called to challenge a problem we could reach along with our partner TECNOALLOY the success by applying our techniques and approach .